Asphalt Installation

Snow Melting Mats & Cable

Snow melting systems from WarmlyYours can greatly improve your outlook on the winter months. Imagine not having to shovel the snow or worry about slipping on ice on your walkways and driveway. Our snow melting systems install underneath asphalt, concrete or pavers, and the installation instructions are tailored to each surface. Electricians and paving contractors typically take care of the installation—it’s not generally a do-it-yourself project as it’s relatively involved.

Driveway heating systems are a great addition to any home if you’re looking to add a bit of luxury and convenience to your living space. You’ll no longer have to worry about getting snowed in or have to spend time before going to work shoveling the driveway. When you come home from the grocery store with arms carrying a lot of bags, you won’t have to worry about slipping on ice or snow, because the snow melting system will have already taken care of it for you.

Start enjoying the benefits of WarmlyYours’ snow melting systems today. Follow this asphalt snow melting systems installation guide, and put the shovel away for good. Please Note: This is an installation guide for Snow Melting Systems with Asphalt, you can also find out how to install with Concrete or with Pavers.

Getting Started

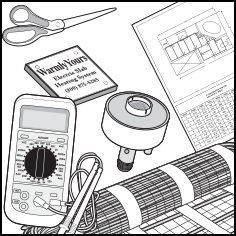

Material and Tools Required:

- WarmlyYours Snow Melt Mats and/or Cables

- Controller, sensor(s), relay panel and Plaque

- Custom Design Layout (provided FREE with order)

- Digital Ohms Meter & 500 VDC Digital Megohm Meter (Megger)

- Amp Meter, Plastic cable ties, & Scissors

Please call WarmlyYours (800) 875-5285 for 24/7 installation and technical support if needed.

Step 1 - Electrical Rough-In

The electrician will supply appropriately sized breakers that are 30mA trip GFPE type for each heater circuit. The relay panel(s) must be installed, and power routed from the breakers to the relay panel(s). The electrician should complete any outdoor trenching needed for routing power to the heated zone. All outdoor rated junction box(es) required for cold lead extensions / splicing should be installed at this time. Control panel, relay(s), aerial mount sensor(s) (if used) and associated wiring should be installed.

Step 2 - Mat Heater Installation

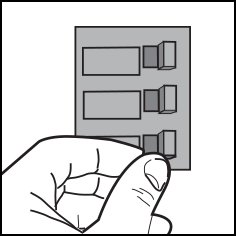

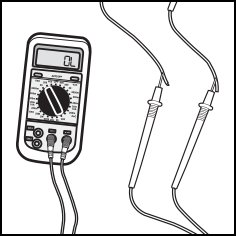

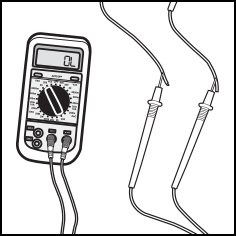

When material order shipment arrives, use ohms meter to test each mat heater (between the two conductors), and verify number with the UL tag. Also, test each heating mat for megohms (between conductor and yellow/green ground wire). The Megohm Meter (500 VDC) tests for insulation resistance around the conductor(s), and should read infinite, OL, or a minimum of 10 megohms.

Step 3 - Basic Preparation

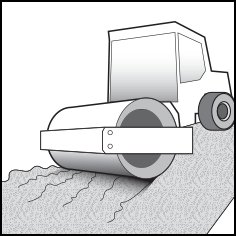

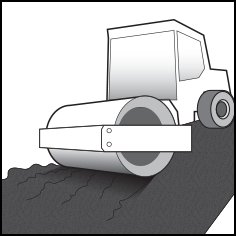

Paving contractor should ensure that the base has at least 8" to 12" of crushed rock aggregate that has been spread, and steam-rolled over.

Step 4 - Lay 1st Asphalt Pour

The paving contractor lays the 1st hot asphalt base/primer layer ( 2” thick ), and steam rolls over it.

Step 5 - Mat & OT Sensor Placement During 2nd Asphalt Pour

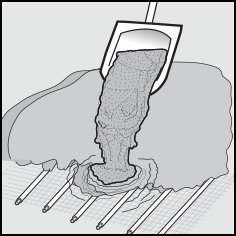

The electrician must place each mat, as per the Custom Design Layout Drawing (provided by WarmlyYours). A portion of each mat is rolled out (4' to 8'), and asphalt is dumped over the flat portion with a Shovel Loader. The dumped asphalt must be manually spread with rakes and shovels over the heating mats (the rakes & shovels must NOT make any direct contact with the mat heaters) to an even depth of 2" to 3". Asphalt spreader machines are NOT allowed. Asphalt temperatures must not exceed 350°F. Heavy trucks & equipment must NOT run over any exposed heating cable, sensors, conduit, or cold leads. During burial, the OT (Over Temperature) Sensor and slab sensor (if applicable) conduits (3/4" rigid metal) must be placed without the sensor(s) inside, between two heating cable passes, or between two mats. Once the mat heaters, and sensor conduit(s) and associated sensor hardware have been covered evenly with 2" to 3" of hot asphalt, then the paving contractor is free to steam roll over them. The electrician should continuously test the mat heaters with an ohms meter. See Installation Manual for more details concerning SCE-SLAB-SS-KIT and OT sensor installation. Always ohm test sensors before installation!

Step 6 - Re-test Mat Heaters

The electrician takes a final ohms & megohm test on each mat after the asphalt has cooled to a temp lower than 100&def;F. and complete the warranty documents with all test results.

Step 7 - Final Wiring & Amp Testing

Electrician should complete all wire splicing in the junction box(es). The OT Sensor should be inserted into its conduit using "fish-tape."" Sensor wire splicing should be completed. Any associated control or relay panel wiring should be completed. Breakers should be turned ON, sensor(s) should be tested, and the system should be activated (manually, or with ice, snow or ice water), to allow the electrician to check amperage of each heater.