Deicing Systems for Accessibility Ramps

Accessibility ramps must remain clear and safe at all times—snow and ice are not just an inconvenience, they're a serious safety hazard.

Our electric snow melting systems install directly in concrete, asphalt, or beneath pavers to automatically keep ramps clear throughout winter.

Follow our detailed guide and learn how to install an accessibility ramp with a snow melting system that will increase safety for everyone.

Why Heat Your Accessibility Ramps?

What is Snow Melting?

Have you ever seen snow fall on an already warm car? It melts instantly. This is the essential idea behind snow melting systems—a heating element is embedded in your ramp and it melts the snow that falls on it.

Like any outdoor surface, an accessibility ramp can benefit from installing a WarmlyYours snow melting system (available in both mats and cables).

Designed to install directly in concrete, asphalt, or in mortar beneath pavers, our systems ensure safe passage for everyone.

Learn More About Snow MeltingFree SmartPlan

Get a custom installation plan for your accessibility ramp in just 1 business day.

"I'll design a custom snow melting layout for your project, complete with cable spacing, electrical requirements, and a full quote."

When to Install a Snow Melting System

Because the snow melting system is embedded within the surface itself, the best time to install is when a ramp is being created for the first time, redone, or expanded.

These projects are typically undertaken from late spring to late fall when ground temperatures are above freezing and you can avoid icing conditions during concrete installations.

The snow melting heating elements must be installed approximately 2-3" beneath the finished surface to ensure optimal warming for ice protection.

The thinness of our cables (1/4") means minimal impact on the overall ramp depth.

Installing the Snow Melting System

For a snow melting system to function properly, it must be located 2-3" from the finished surface throughout the entire heated area. This means your system must match the slope of your ramp.

Follow these steps for a successful accessibility ramp installation:

Step 1. Slope and Rise

Your snow melting system must match the slope of your ramp to maintain the proper 2-3" depth from the finished surface throughout.

Tip: Use bricks and rebar as an elevating base to set the wire mesh at the proper angle.

Step 2. Laying Down Rebar or Wire Mesh

For snow melting cables, include a rigid framework for the cables to attach to. This ensures proper spacing and depth in the finished project.

Secure the framework so it lies flat, then attach cables with zip-ties.

Step 3. Start Laying Out Snow Melting Cables

Maintain 3" (76mm) spacing for free-form cables. Attach to the framework using wire ties to maintain proper depth and spacing.

Reference your free WarmlyYours SmartPlan for proper layout guidance.

Step 4. Preparation for Handrails

For ramps with handrails, install pre-sleeves for the posts to avoid drilling through the finished surface.

Route heating cable around sleeves—never allow direct contact with metal fixtures.

Step 5. Pouring Concrete

Use 1-stage or 2-stage pours. For 2-stage: pour base layer, lay framework while wet, then apply 2-3" top layer. For 1-stage: prop up framework and pour around it.

See the WarmlyYours installation manual for detailed instructions.

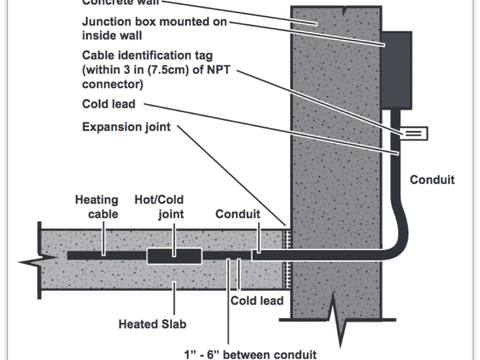

Embed the Manufacturer's Splice

A common mistake is leaving the splice outside of the concrete. This causes the splice to overheat and fail.

Always embed the splice in concrete, sand, or stone dust to prevent overheating. Your ramp is then ready—just add snow!

Controls for Ramp Snow Melting

WarmlyYours offers a wide variety of controls—from manual options with timers to automatic controls that activate when they sense snow is falling.

For accessibility ramps, we strongly recommend automatic controls to ensure the ramp is always clear when needed. Controls use slab sensors (to measure surface conditions) or aerial sensors (to detect snowfall).

For more information, check out this comparison chart.

Shop ControlsSnow Melting Products for Accessibility Ramps

Cables are typically preferred for ramps as they offer maximum flexibility for sloped installations and custom layouts.

Maximum Flexibility at a Minimal Cost

-

High Heat Output: This embeddable electric heating cable provides 12-watts of heat per linear foot (nearly 50-watts per sq. ft.)

-

Embeddable in Concrete, Asphalt, or in Mortar Under Pavers: Installing a cable-based snow melting system within a new driveway, walkway, or patio means you can enjoy snow/ice free outdoor surfaces all year

-

Cost-Effective and Flexible: Snow melting cables are an less expensive (but more time consuming) alternative to snow melting mats and they provide maximum flexibility to cover round driveways, cornered patios, or outdoor stairs

-

Wide Variety of Voltages: We offer snow melting cables in 120, 208, 240, and 277 voltages and in a range of different lengths

-

Installation Support: WarmlyYours offers free SmartPlan™ installation plans, 24/7 phone support, and a 10-year limited warranty

Maximum Heat Density for Heavy Snowfall (3" spacing)

-

Maximum Heat Output: Approximately 50-watts per sq. ft with 3" cable spacing for fastest snow melting

-

Best for Heavy Snowfall: Recommended for regions with 60+ inches of annual snowfall or when rapid melting is critical

-

Even Heating: Pre-attached heating elements in a serpentine pattern with consistent 3" spacing ensures uniform coverage

-

Fast and Easy Installation: Cut-and-turn design makes installation faster than cables while providing maximum heat density

-

Installation Support: Free SmartPlan™ installation plans, 24/7 phone support, and a 10-year limited warranty

Optimal Performance & Energy Balance (4" spacing)

-

Balanced Heat Output: Approximately 39-watts per sq. ft with 4" cable spacing for optimal performance and efficiency

-

Best for Moderate Snowfall: Recommended for regions with 30-60 inches of annual snowfall—our most popular choice

-

Even Heating: Pre-attached heating elements in a serpentine pattern with consistent 4" spacing ensures uniform coverage

-

Fast and Easy Installation: Cut-and-turn design makes installation faster than cables while balancing cost and performance

-

Installation Support: Free SmartPlan™ installation plans, 24/7 phone support, and a 10-year limited warranty